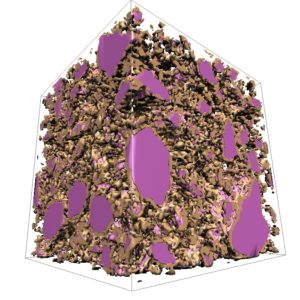

We have developed several computational materials science models to simulate 3D microstructure evolution of multiphase materials, especially porous media. The phenomena we seek to capture are the rates of dissolution, nucleation, and growth of solid phases, the evolution in the composition of those phases, and morphological changes. We endeavor to make these models as fundamental as possible at length scales of about 100 nm to 100 μm.

THAMES

|

THAMES (Thermodynamic Hydration And Microstructure Evolution Software) is a 3D lattice-based model of microstructure development that can be used when a large portion of a material system is evolving slowly under near-equilibrium conditions. It uses geochemical thermodynamic equilibrium calculations to predict solid-phase assemblages and solution speciation for boundary conditions that are evolving in time due to changes in the surroundings. A digital-image-based model is used to arrange those phases to create a realistic microstructure that can subsequently be coupled to finite element models to calculate the evolving mechanical and transport properties. THAMES has recently been used to model portland cement hydration, the viscoelastic properties of cementitious binders, and the evolution of cement properties during groundwater leaching and external sulfate attack. More … |

HydratiCA

| HydratiCA is a 3D kinetic cellular automaton with probability rules that can be proven to converge to standard reaction rate equations in the continuum limit. It can simulate mass transport and multiple chemical reactions over a wide range of chemical driving forces. It has been applied recently to help understand the mechanisms of the hydration of tricalcium silicate, the primary mineral component of portland cement that is responsible for early-age strength development of concrete. More … |  |

VCCTL

| VCCTL (Virtual Cement and Concrete Testing Laboratory) is a software package created at the National Institute of Standards and Technology (NIST) to model the hydration and properties of portland cement and concrete. Our group continues to maintain and develop VCCTL. More … |

MicroChar

| MicroChar is a small software package that assists with the characterization of microstructures observed by quantitative SEM and Electron Microprobe Analysis. Given a digitized and indexed 2D micrograph of a microstructure, MicroChar can perform measurements of the phase area fractions, surface boundary fractions, and various autocorrelations functions to quantify the spatial arrangement of the phases. It can also collect and package the data for direct input into the VCCTL software package. |